Morris Lubricants urges farmers to prioritise engine oil performance with its top five maintenance tips

Morris Lubricants urges farmers to prioritise engine oil performance with its top five maintenance tips

Morris Lubricants is advising farmers to put oil, lubricant and grease performance ahead of price as they prepare their tractors for the new season

With rising prices, such as the steep increase in fertiliser costs having a significant impact on the sector, it can be tempting to look for short term savings elsewhere. In a market dominated with cheap imports, choosing an alternative oil to the manufacturer’s specification, at a lower price, may seem like a sound investment.

However, says Adrian Hill, Morris Lubricants' Technology Manager, selecting the wrong, and usually, an inferior quality oil may result in significant, long-term consequences to equipment performance and in the end an overall increase in running cost.

Adrian outlines the company’s top tips for farmers as they prepare their vehicles for the new season.

Quality first

Modern tractor engines are now designed to meet Stage V emissions compliance for off-highway vehicles, to meet the latest emissions legislation. These will include after treatment devices, such as AdBlue systems, diesel oxidation catalysts and diesel particulate filters, to limit harmful particulate matter and NOx emissions.

Selecting the correct, high-quality oil will more than pay for the higher purchase price in the long run. For example, an incorrectly specified engine oil can block these catalysts or filters, potentially leading to significant remedial costs in the region of £3,000 or more for the replacement part, plus the additional cost of the repair and downtime itself.

Service intervals

Investing in a new or modern tractor is a significant capital expense, and farmers and farming contractors need the assurance that the investment will perform reliably over many years. After the initial three-year manufacturer’s service schedule, some owners may choose to delay future servicing, but this can prove a false economy. Engine oil over time may start to degrade, causing damage to vital engine components, so it is always advisable to meet the manufacturer’s recommended service intervals.

Right oil for the right job

Some older machinery may have always operated reliably using a universal tractor oil, but modern diesel particulate filters in particular can be sensitive to these universal oils. Instead, farmers should ensure they are using the correct oils for both the engine and the transmission (back end) systems.

Seek technical advice

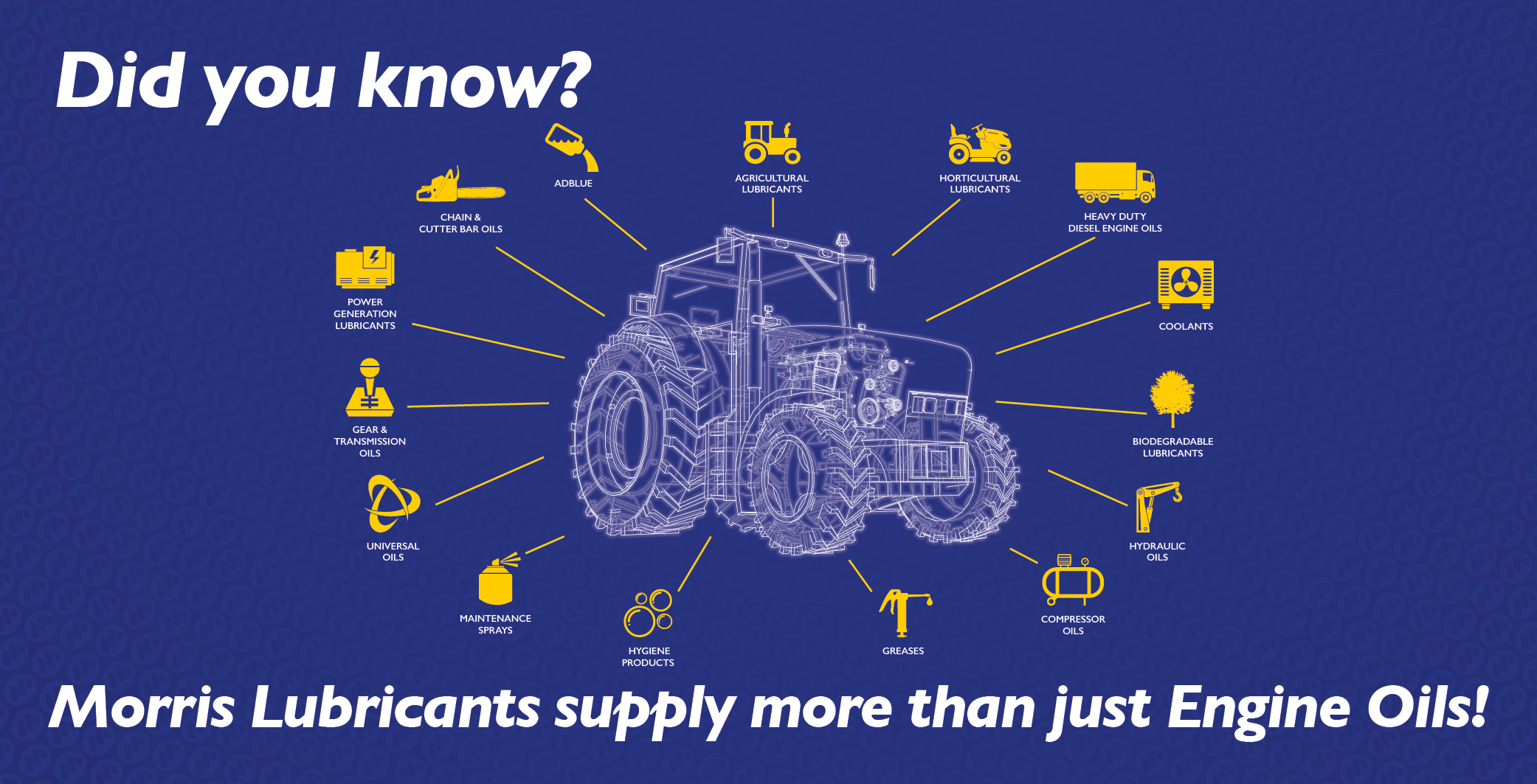

Machinery downtime is not only costly but can damage reputation if stock or deliveries are affected. Seeking professional advice regarding the correct engine oil specification, or service intervals will always pay dividends. Morris Lubricants has a dedicated team of experts to provide the latest oil, lubricant and grease recommendations for a wide variety of agricultural vehicles and equipment. Whether it's a tractor, combine harvester, mini digger, all terrain vehicle (ATV) or any other agricultural machinery the technical team have the appropriate solution to keep your vehicles out working in the field, rather than stuck in the workshop. You can contact Adrian and his team of experts on (01743 237541) or email technicalhelpdesk@morris-lubricants.co.uk.

Choose performance not price

Adrian concludes,

“Choosing the right engine oil for the right tractor is a key part of the equipment lifecycle. It should be seen as a cost-effective and proactive means of protecting engine performance and ensuring equipment longevity.

“The fifth and probably the most important tip is to be guided by performance and not purchase price. This will ensure that farmers do not need to spend additional budget, at a time when costs are already at a premium, on unnecessary repair work.

About the Agrimax range

Agrimax is an innovative range of advanced multifunctional lubricants for the agricultural industry, manufactured at the Morris Lubricants facility in Shrewsbury.

Agrimax is designed to help reduce downtime, improve fuel efficiency and contribute to the reduction in engine emissions.